-

Posts

4,074 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

News for Home Inspectors

Blogs

Gallery

Store

Downloads

Everything posted by John Dirks Jr

-

-

72 degree ambient. System hasn’t been run in two days. Vapor side reading 150psi at idle (not running) So, this indicates there has not been a loss of refrigerant. Am I correct?

-

When refrigerant is recovered prior to the proper recharging of a system, can that recovered portion be put back in? Obviously you would weigh it. Then add the remaining weight to top off the system?

-

I’m not yet convinced that brazing will be needed. We will see what happens when the tools get here.

-

I have a MAP torch. Is that good enough?

-

Tech guy at Mr Cool is suspicious of improper refrigerant charge, either high or low. I ordered my own manifold gauge set. When it gets here and I get the numbers, I’ll post back. He wants to see 120-150psi in 80 degree ambient.

-

Marc, you have been a great help. Double checking my thought process is important. Tomorrow I will call the Mr Cool tech line. I’ll let you know how that discussion goes.

-

Then wouldn’t that mean the low pressure line would be frosting? Because it’s the high pressure side returning from the evap that’s frosting, not the low side.

-

The lines are currently concealed at the evap end. However the visible portions of high line on the exterior of the condenser do frost up. And that frosting continues up the line into the jacket. But I can’t see very far up the jacket.

-

The reversing valve is in the condenser just above the little coiled lines we’ve been discussing. I don’t know how to determine if the compressor is inverter-fed.

-

I made a mistake in this post. I mentioned evap core in two places. In both instances I meant to say condenser core. Also, I cant believe I have not mentioned this yet but the system has built in leak detection which shows "EC" on the indoor unit display when leakage is detected. Considering my lost performance, if refrigerant loss were the cause, that's a substantial amount of loss. Surely enough loss to trigger the detection system to signal loss, I would think. I've gotten no "EC" display signals.

-

I think its purpose is simply to transition from the larger diameter portion of the high side line back into the two smaller ones, just like in the line set. As I said before, the line set high side is comprised of two very small lines that transition into on larger line at the attachment to the evap and the fitting at the condenser. Then, after going through the fitting and into the condenser case, it splits back into the two smaller lines.

-

The second coiled line you see in the back loops right back to the high side line. It’s like this. There’s larger line that comes through the case from the fitting (high side). This line goes into a bubble like thingy. Then the two tiny coiled lines come out of the other side of the bubble. One of the coiled lines goes to the evap core. The other coiled line just returns to this bubble thingy that it came from. So, the way I see it, both tiny coiled lines are on the high side. Because one just comes from the high line, then returns right back to it. So, for any refrigerant to pass through the evap, no matter what direction or mode, it has to pass through the tiny coiled line in the foreground of the pictures.

-

Well, one side of that tiny coiled high line frosts in the heat cycle, and the other side in the cooling cycle. I can duplicate over and over and it happens quickly. Like nothing is passing through that tiny coil.

-

Will do. My acquaintance with HVAC experience was here earlier but his gauge set didn’t fit the new larger 410a fitting on this unit. I have an adapter on order and it should be here tomorrow. Now, if the gauge confirms the charge is still with in normal range, then would you be suspicious of a blockage?

-

I used dish washing detergent on the fittings both while shut down and in operating modes. No signs of leaks at the fittings whatsoever. When put in cooling mode, the frosting of the high side line happens really quick. Like 30 seconds it begins and by one minute it’s frosted over totally. It’s not humid at all here today. Are we sure there’s no chance of an internal blockage?

-

I’ll do that Marc. Meanwhile, here’s another question while we’re at it. Is it possible for the leak to happen only at higher pressures, such that if I check it after being shut down for a while it won’t show leakage? But start it up, build pressure, then leaks are evident?

-

-

Jim, there are special fittings on the line set. The line set is attached at the evaporator unit from the factory. You feed the lines through the wall and lift the evap into place. Run lines to condenser unit and attach. The fitting has some sort of check valve that gets forced open as you tighten the nut. The instructions say to work quickly through the fitting connection process and that there may be some slight leakage during such. Maybe there’s a leak like Marc suspects. Maybe I didn’t tighten the fittings enough. I’m going to search for leaks, hopefully find them, fix them, evacuate, recharge and cross fingers.

-

No doubt there is a problem. I can get a 20+ degree differential in the heat mode. 70 in 93 out. In the cooling mode, very little temp drop, especially after the line frosts up. And it is the high line frosting up. Cooling diff just a few degrees at best. While it was working good prior to the issue, condensate would be coming out the drain line and running down the driveway in a stream. Now, it still comes out but only in a faint trickle. Again, good exchange on heat cycle, poor exchange in cooling. The head unit does not have electric backup heat so the exchange in the heat cycle suggests that maybe the refrigerant charge is ok. But I’m not sure of that.

-

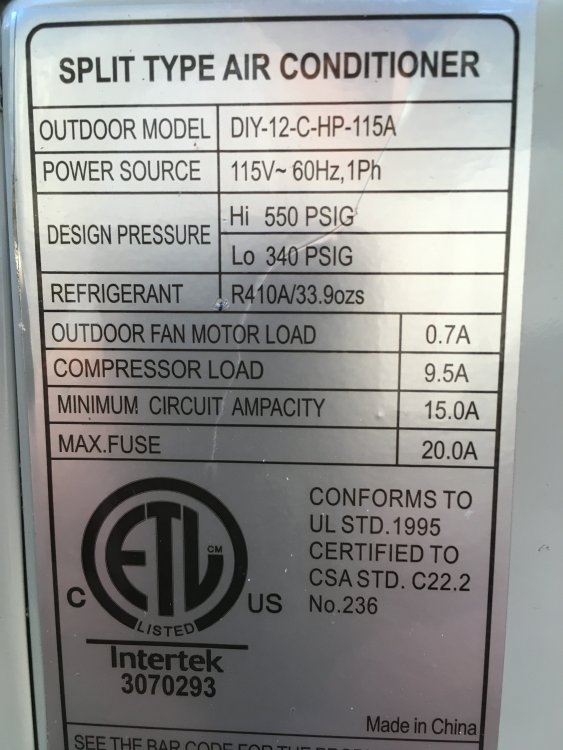

Hi folks, I recently installed a Mr Cool DIY mini split system. This one It comes with a pre charged line set. The installation went well and the system worked fantastic for a few weeks but then the cooling performance dropped substantially. I noticed the the high side line frosting up and a little research tells me that blockage in the line set is a likely culprit. I removed the panel to observe the innards and ran the system to watch. Now, please understand that on this system, the high side line exists of two very small lines that run the distance from the evap to the condenser. The only exception is these two tiny lines come together into a larger line at the fitting connection to the condenser unit. Then, they split back into two tiny lines inside of the condenser body. From there, one of the tiny lines loops back to the junction and the other goes through what looks like a small inline filter or dryer. At the other side of this little inline thing, the line gets larger and runs directly to the bottom of the condenser core. In the pictures below you'll see the tiny high side line spun in a coil. During my observations, one side of the coiled line frosts up during the heat cycle, and the other side frosts up during the cooling cycle. This makes me think there is a blockage in this coiled portion of high side line. What do you think? Blockage here or possibly something else to consider? If it is a blockage here, is there a way to clear it up or am I left with hiring a pro to cut out and replace the blocked portion? First pic shows frosting during heat mode. Second picture shows frosting during cooling mode. I'm thinking theres blockage in the tiny coiled line.

-

Who needs a junction box? Just screw the receptacle directly too the wall and wrap it up baby! I thought a whole roll of tape cost more than a junction box.

-

Came across these steel shims, thoughts?

John Dirks Jr replied to Brothers's topic in Foundation Systems Forum

The pocket may even be too shallow. Might need to install a column to supplement bearing. -

Ive had GL only from Selective for 12 years now https://www.selective.com/

-

Ah Ha! They still make it! https://www.fenix-store.com/fenix-tk15-ultimate-edt-led-flashlight/